Umgomo wethu oyisiqondiso ukuhlonipha umklamo wangempela wekhasimende kuyilapho sisebenzisa amakhono ethu okukhiqiza ukuze sakhe ama-PCB agcwalisa lokho okucaciswe yikhasimende. Noma yiziphi izinguquko ekwakhiweni kwasekuqaleni zidinga imvume ebhaliwe evela kukhasimende. Lapho bethola isabelo sokukhiqiza, onjiniyela be-MI bahlola ngokucophelela yonke imibhalo nolwazi olunikezwa ikhasimende. Ziphinde zihlonze noma yikuphi ukungqubuzana phakathi kwedatha yekhasimende namandla ethu okukhiqiza. Kubalulekile ukuqonda ngokugcwele izinhloso zokuklama zekhasimende kanye nezidingo zokukhiqiza, ukuqinisekisa ukuthi zonke izidingo zichazwe ngokucacile futhi ziyakwazi ukwenzeka.

Ukuthuthukisa idizayini yekhasimende kuhilela izinyathelo ezihlukahlukene njengokuklama isitaki, ukulungisa usayizi wokumba, ukunweba imigqa yethusi, ukukhulisa iwindi lemaski ye-solder, ukulungisa izinhlamvu efasiteleni, nokwenza ukwakheka kwesakhiwo. Lezi zinguquko zenziwa ukuze zihambisane nazo zombili izidingo zokukhiqiza kanye nedatha yedizayini yangempela yekhasimende.

Inqubo yokudala i-PCB (Ibhodi Lesifunda Eliphrintiwe) lingahlukaniswa kabanzi libe yizinyathelo ezimbalwa, ngasinye sibandakanye amasu okukhiqiza ahlukahlukene. Kubalulekile ukuqaphela ukuthi inqubo iyahlukahluka kuye ngesakhiwo sebhodi. Izinyathelo ezilandelayo ziveza inqubo evamile ye-PCB enezingqimba eziningi:

1. Ukusika: Lokhu kuhlanganisa ukusika amashidi ukuze kusetshenziswe kakhulu.

2. Ukukhiqizwa Kwesendlalelo Sangaphakathi: Lesi sinyathelo ngokuyinhloko esokudala ukujikeleza kwangaphakathi kwe-PCB.

- Ukwelashwa kwangaphambili: Lokhu kuhlanganisa ukuhlanza indawo engaphansi ye-PCB kanye nokukhipha noma yikuphi ukungcola okungaphezulu.

- Lamination: Lapha, ifilimu eyomile inamathele endaweni engaphansi ye-PCB, ilungiselela ukudluliswa kwesithombe okulandelayo.

- Ukuchayeka: I-substrate eboshiwe ivezwa ekukhanyeni kwe-ultraviolet kusetshenziswa okokusebenza okukhethekile, okudlulisa isithombe se-substrate kwifilimu eyomile.

- I-substrate eveziwe ibe isithuthukiswa, iqoshwe, futhi ifilimu iyasuswa, iqedela ukukhiqizwa kwebhodi lesendlalelo sangaphakathi.

3. Ukuhlola Kwangaphakathi: Lesi sinyathelo ngokuyinhloko esokuhlola nokulungisa amasekhethi ebhodi.

- Ukuskena okubonakalayo kwe-AOI kusetshenziselwa ukuqhathanisa isithombe sebhodi le-PCB nedatha yebhodi lekhwalithi enhle ukuhlonza amaphutha afana nezikhala namabotho esithombeni sebhodi. - Noma yiziphi izinkinga ezitholwe yi-AOI zibe sezilungiswa yizisebenzi ezifanele.

4. Lamination: Inqubo yokuhlanganisa izingqimba eziningi zangaphakathi zibe ibhodi elilodwa.

- I-Browning: Lesi sinyathelo sithuthukisa isibopho phakathi kwebhodi ne-resin futhi sithuthukisa ukumanzisa kwendawo yethusi.

- I-Riveting: Lokhu kuhilela ukusika i-PP kusayizi ofanele ukuhlanganisa ibhodi lesendlalelo sangaphakathi ne-PP ehambisanayo.

- Ukucindezela Ukushisa: Izendlalelo zicindezelwa ngokushisa futhi ziqiniswe zibe iyunithi eyodwa.

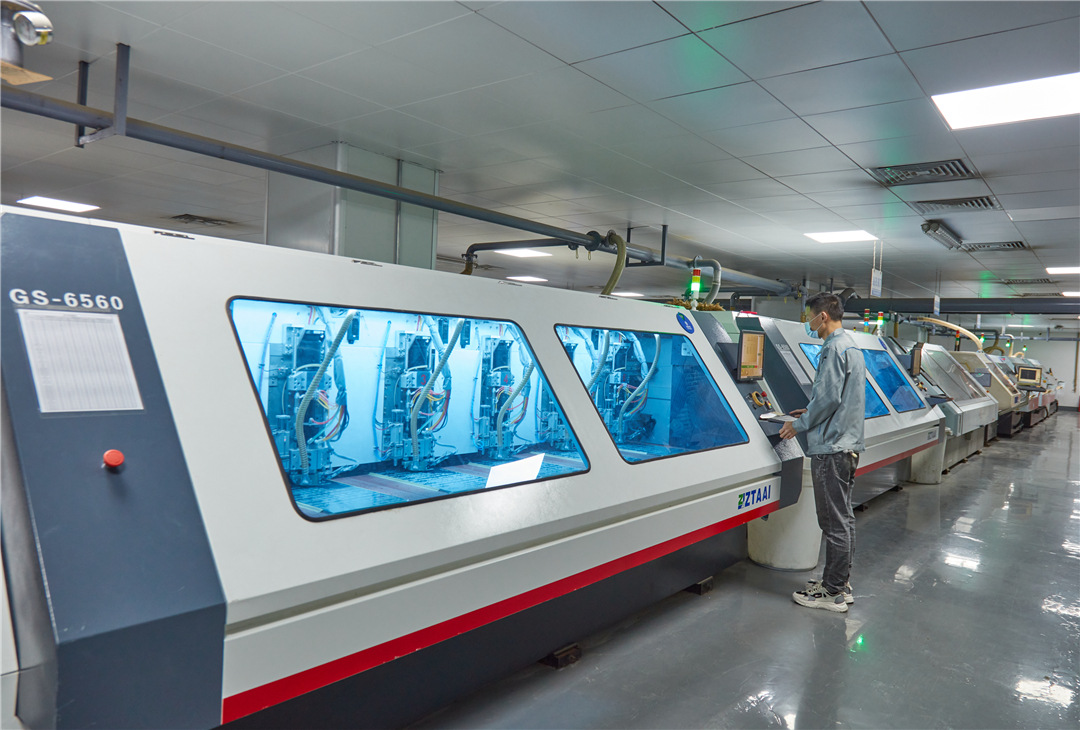

5. Ukubhoboza: Umshini wokubhoboza usetshenziselwa ukudala izimbobo ezinobubanzi obuhlukahlukene nosayizi ebhodini njengokucaciswa kwamakhasimende. Lezi zimbobo zisiza ukucutshungulwa kwe-plugin okulandelayo futhi zisize ekulahlekeni kokushisa okuvela ebhodini.

6. I-Copper Plating Eyisisekelo: Izimbobo ezibhoboziwe ebhodini zifakwe ithusi ukuze kuqinisekiswe ukuhamba kuzo zonke izingqimba zamabhodi.

- Ukuqothula: Lesi sinyathelo sihilela ukususa ama-burrs emaphethelweni embobo yebhodi ukuvimbela ukufakwa kwethusi okungekuhle.

- Ukususwa kweGlue: Noma iyiphi insalela yeglue ngaphakathi komgodi iyasuswa ukuze kuthuthukiswe ukunamathela ngesikhathi sokucwiliswa okuncane.

- I-Hole Copper Plating: Lesi sinyathelo siqinisekisa ukusebenza kuzo zonke izendlalelo zebhodi futhi sandise ukushuba kwethusi.

7. Ukucutshungulwa Kwesendlalelo Sangaphandle: Le nqubo ifana nenqubo yesendlalelo sangaphakathi esinyathelweni sokuqala futhi yakhelwe ukwenza lula ukudalwa kwesekethe okulandelayo.

- Ukwelashwa kwangaphambili: Ingaphezulu lebhodi lihlanzwa ngokucotshwa, ukugaywa, nokomiswa ukuze kuthuthukiswe ukunamathela kwefilimu eyomile.

- Lamination: Ifilimu eyomile inamathela endaweni engaphansi ye-PCB ukulungiselela ukudluliswa kwesithombe okulandelayo.

- Ukuchayeka: Ukuchayeka kokukhanya kwe-UV kubangela ifilimu eyomile ebhodini ukuthi ingene esimweni se-polymerized ne-unpolymerized.

- Ukuthuthukiswa: Ifilimu eyomile engena-polymerized iyachithwa, ishiye igebe.

8. I-Copper Plating yesibili, i-Etching, i-AOI

- I-Secondary Copper Plating: Iphethini ye-electroplating kanye nokufakwa kwamakhemikhali ethusi kwenziwa ezindaweni ezisemigodini engamboziwe ifilimu eyomile. Lesi sinyathelo siphinde sibandakanye ukunwetshwa kwe-conductivity kanye nogqinsi lwethusi, kulandelwa ukufakwa kwe-tin ukuze kuvikelwe ubuqotho bemigqa nezimbobo ngesikhathi sokuqoshwa.

- I-Etching: Isisekelo sethusi endaweni enamathiselwe kwifilimu eyomile yangaphandle (ifilimu emanzi) siyasuswa ngokusebenzisa ifilimu yokuhlubula, i-etching, kanye nezinqubo zokukhumula ithini, kuphothulwe isifunda sangaphandle.

- I-Outer Layer AOI: Ngokufana nongqimba lwangaphakathi lwe-AOI, ukuskena kwe-AOI kusetshenziswa ukukhomba izindawo ezinokukhubazeka, ezibuye zilungiswe izisebenzi ezifanele.

9. Isicelo Semaski ye-Solder: Lesi sinyathelo sibandakanya ukusebenzisa imaski ye-solder ukuvikela ibhodi nokuvimbela i-oxidation nezinye izinkinga.

- Ukwelashwa Kwangaphambi Kokuqala: Ibhodi liyahlolwa futhi liwashwe nge-ultrasonic ukuze lisuse ama-oxides futhi likhulise ukuqina kwendawo yethusi.

- Ukuphrinta: Uyinki wokuphikisa we-Solder usetshenziselwa ukumboza izindawo zebhodi le-PCB ezingadingi ukufakwa kwe-solder, ukuhlinzeka ngokuvikelwa kanye nokufakwa kwe-insulation.

- Ukubhaka ngaphambilini: I-solvent kuyinki yemaski ye-solder yomile, futhi uyinki uyaqina ukulungiselela ukuchayeka.

- Ukuchayeka: Isibani se-UV sisetshenziselwa ukwelapha uyinki yemaski ye-solder, okuholela ekwakhekeni kwe-polymer ephezulu yamangqamuzana ngokusebenzisa i-photosensitive polymerization.

- Ukuthuthukiswa: Isixazululo se-sodium carbonate ku-inki engafakwanga i-polymerized siyasuswa.

- Ngemuva kokubhaka: Uyinki uqiniswe ngokuphelele.

10. Ukuphrinta Umbhalo: Lesi sinyathelo sibandakanya ukuphrinta umbhalo ebhodini le-PCB ukuze ubhekwe kalula phakathi nezinqubo zokunamathisela ezilandelanayo.

- I-Pickling: Ingaphezulu lebhodi liyahlanzwa ukuze kukhishwe i-oxidation futhi kuthuthukise ukunamathela kukayinki wokuphrinta.

- Ukuphrinta Umbhalo: Umbhalo ofisa ukuphrinta ukuze kube lula izinqubo zokushisela ezilandelayo.

11.Ukwelashwa Okungaphezulu: Ipuleti le-copper elingenalutho liphathwa phezulu ngokusekelwe ezidingweni zekhasimende (njenge-ENIG, HASL, Silver, Tin, Plating gold, OSP) ukuze kuvinjelwe ukugqwala kanye ne-oxidation.

12.Iphrofayili Yebhodi: Ibhodi lakhiwe ngokuvumelana nezidingo zekhasimende, lisiza ukupheshela nokuhlanganisa i-SMT.

14. Ukuhlola Ikhwalithi Yokugcina (FQC): Ukuhlolwa okuphelele kwenziwa ngemva kokuphothula zonke izinqubo.