Impahla yelabhorethri ebonakalayo neyamakhemikhali:

Ukuhlolwa kwemishini, ukuhlolwa kukagesi, ukuhlolwa kwebhodi lokuqala nokuhlola, ukuhlaziya ilabhorethri.

1. Umhloli we-copper foil tensile: Leli thuluzi lisetshenziselwa ukukala amandla e-foil yethusi phakathi nenqubo yokwelula. Kuyasiza ukuhlola amandla nokuqina kwe-copper foil ukuze kuqinisekiswe ikhwalithi yomkhiqizo nokuthembeka.

I-Copper Foil Tensile Tester

Umshini Wokuhlola Isifutho Sikasawoti Ohlakaniphile Ngokugcwele

2. Umshini wokuhlola isifutho sikasawoti esihlakaniphe ngokugcwele: Lo mshini ulingisa indawo yesifutho sikasawoti ukuze uhlole ukumelana nokugqwala kwamabhodi esekethe ngemva kokwelashwa kwendawo. Isiza ukulawula ikhwalithi yomkhiqizo futhi iqinisekise ukusebenza okuzinzile ezindaweni ezinokhahlo.

3. Umshini wokuhlola izintambo ezine: Leli thuluzi lihlola ukumelana nokuhamba kwezintambo kumabhodi esekethe aphrintiwe. Ihlola ukusebenza kukagesi kwebhodi, okuhlanganisa ukusebenza kokudlulisela kanye nokusetshenziswa kwamandla, ukuze kuqinisekiswe ukuxhumana okuthembekile nokuzinzile.

Umshini Wokuhlola Onezintambo Ezine

4. Umhloli we-Impedans: iyithuluzi elibalulekile ekwenzeni ibhodi lesifunda eliphrintiwe. Isetshenziselwa ukukala inani le-impedance ebhodini lesifunda ngokukhiqiza isignali ye-AC ye-fixed-frequency edlula kumjikelezo ngaphansi kokuhlolwa. Isekhethi yokulinganisa ibe isibala inani le-impedance ngokusekelwe emthethweni we-Ohm nezici zamasekhethi e-AC. Lokhu kuqinisekisa ukuthi ibhodi lesifunda elikhiqiziwe lihlangabezana nezidingo ze-impedance ezibekwe yikhasimende.

Abakhiqizi bangaphinda basebenzise le nqubo yokuhlola ukwenza ukuthuthukiswa kwenqubo futhi bathuthukise amandla okulawula okuthikamezeka kwamabhodi esekethe. Lokhu kuyadingeka ukuze kuhlangatshezwane nezidingo zokudluliswa kwesiginali yedijithali enesivinini esikhulu kanye nezicelo zamafrikhwensi omsakazo.

I-Impedans Tester

Kuyo yonke inqubo yokukhiqiza ibhodi lesifunda, ukuhlolwa kwe-impedance kwenziwa ngezigaba ezahlukahlukene:

1) Isiteji sokuklama: Onjiniyela basebenzisa isofthiwe yokulingisa kagesi ukuklama nokuhlela ibhodi lesifunda. Babala kusengaphambili futhi balingise amanani e-impedance ukuze baqinisekise ukuthi umklamo uhlangabezana nezidingo ezithile. Lokhu sekulingisa kusiza ukuhlola i-impedance yebhodi lesifunda ngaphambi kokukhiqiza.

2) Isigaba sokuqala sokukhiqiza: Ngesikhathi sokukhiqizwa kwe-prototype, ukuhlolwa kwe-impedance kwenziwa ukuze kuqinisekiswe ukuthi inani le-impedance lihambisana nokulindelwe. Ukulungiswa kwenqubo yokukhiqiza kungenziwa ngokusekelwe kule miphumela.

3) Inqubo Yokukhiqiza: Ekukhiqizeni amabhodi wesekethe anezingqimba eziningi, ukuhlolwa kwe-impedance kwenziwa ezindaweni ezibucayi ukuze kuqinisekiswe ukulawula phezu kwamapharamitha afana nogqinsi lwe-copper foil, ukujiya kwezinto ze-dielectric, nobubanzi bomugqa. Lokhu kuqinisekisa ukuthi inani lokugcina le-impedance lihlangabezana nezidingo zokuklama.

I-4) Ukuhlolwa komkhiqizo okuqediwe: Ngemuva kokukhiqiza, ukuhlolwa kokugcina kwe-impedance kwenziwa ebhodini lesifunda. Lokhu kuqinisekisa ukuthi izilawuli nokulungiswa okwenziwa kuyo yonke inqubo yokukhiqiza kuhlangabezana ngokuphumelelayo nezidingo zedizayini zevelu ye-impedance.

5. Umshini wokuhlola ukumelana okuphansi: Lo mshini uhlola ukumelana kwezintambo kanye nezindawo zokuxhumana ebhodini lesifunda ukuze kuqinisekiswe ukuthi zihlangabezana nezidingo zokuklama futhi ziqinisekisa ikhwalithi nokusebenza komkhiqizo.

Umshini Wokuhlola Omelana Kaphansi

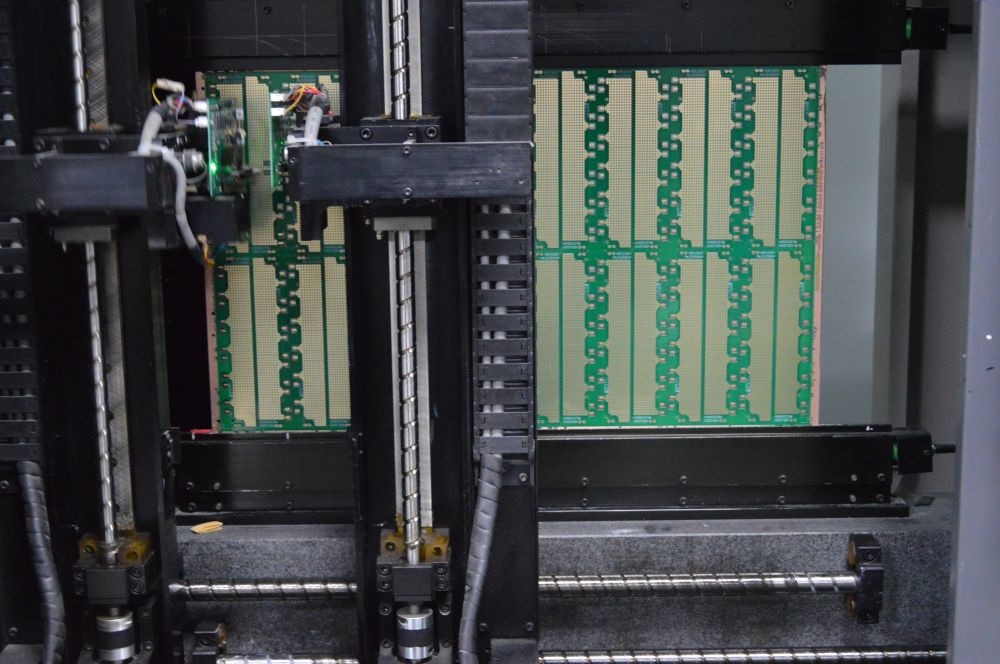

I-Flying Probe Tester

6. Umhloli we-flying probe: Isihloli esindizayo sisetshenziswa ngokuyinhloko ukuhlola amanani e-insulation kanye ne-conductivity yamabhodi esekethe. Ingakwazi ukuqapha inqubo yokuhlola futhi ithole amaphuzu ephutha ngesikhathi sangempela, iqinisekise ukuhlola okunembile. Ukuhlolwa kwe-Flying probe kulungele ukuhlolwa kwebhodi lesifunda leqoqo elincane naphakathi, njengoba kususa isidingo sokulungiswa kokuhlola, kunciphisa isikhathi sokukhiqiza nezindleko.

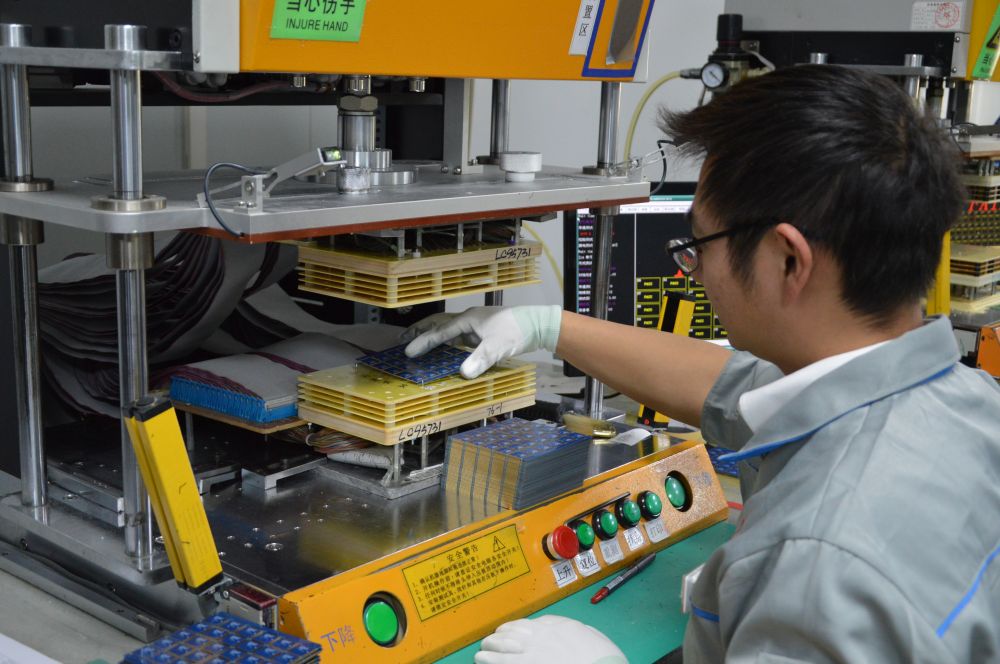

7. Umhloli we-Fixture tooling: Ngokufanayo nokuhlolwa kwe-flying probe, ukuhlolwa kwe-rack rack kuvame ukusetshenziselwa ukuhlolwa kwebhodi lesifunda le-batch eliphakathi nendawo. Ivumela ukuhlolwa ngasikhathi sinye kwamaphoyinti amaningi okuhlola, ithuthukise kakhulu ukusebenza kahle kokuhlolwa kanye nokunciphisa isikhathi sokuhlola. Lokhu kuthuthukisa ukukhiqiza okuphelele komugqa wokukhiqiza, kuyilapho kuqinisekisa ukuthi kunembe futhi kusetshenziswe kabusha kakhulu.

I-Manual Fixture Tooling Tester

I-Automatic Fixture Tooling Tester

Fixture Toolings Store

8. Ithuluzi lokulinganisa elinezinhlangothi ezimbili: Leli thuluzi lithwebula izithombe zendawo yento ngokukhanya nokuthwebula. Ibese icubungula izithombe futhi ihlaziye idatha ukuze ithole ulwazi lwejometri mayelana nento. Imiphumela iboniswa ngokubukeka, ivumela opharetha ukuthi babheke futhi balinganise ngokunembile umumo, usayizi, indawo, nezinye izici zento.

Ithuluzi Lokulinganisa elinezinhlangothi ezimbili

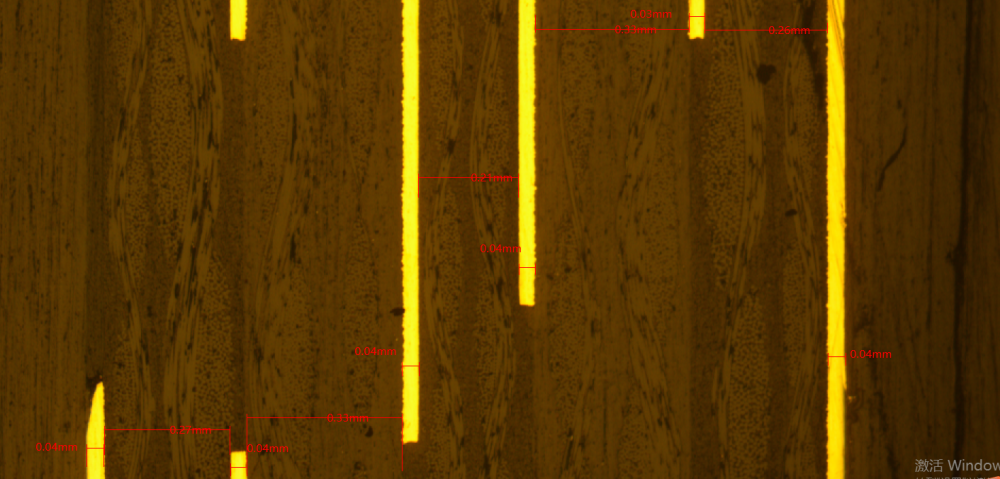

Ithuluzi Lokulinganisa Ububanzi Bomugqa

9. Ithuluzi lokulinganisa ububanzi bomugqa: Ithuluzi lokulinganisa ububanzi bomugqa lisetshenziswa ngokuyinhloko ukukala ububanzi obungaphezulu nobuphansi, indawo, i-engeli, ububanzi besiyingi, ibanga lesikhungo esiyindilinga, kanye neminye imingcele yemikhiqizo engakapheli yebhodi lesifunda ephrintiwe ngemva kokuthuthukiswa nokushumeka (ngaphambi kokuphrinta uyinki yemaski ye-solder). Isebenzisa umthombo wokukhanya ukuze ikhanyise ibhodi lesifunda futhi ithwebule isignali yesithombe ngokusebenzisa i-optical amplification kanye nokuguqulwa kwesignali yesithombe sikagesi we-CCD. Imiphumela yokulinganisa ibe isikhonjiswa kusixhumi esibonakalayo sekhompuyutha, okuvumela ukukala okunembile nangempumelelo ngokuchofoza isithombe.

10. Isithando somlilo sikathayela: Isithando somlilo sethayela sisetshenziswa ukuze kuvivinywe ukuqina kwe-solderability kanye nokumelana nokushaqeka okushisayo kwamabhodi wesekethe, kuqinisekiswe ikhwalithi nokuthembeka kwamalunga e-solder.

Ukuhlolwa kwe-Solderability: Lokhu kuhlola ikhono lebhodi lesifunda ukwenza amabhondi e-solder athembekile. Ikala amaphuzu okuxhumana ukuze ihlole ukuhlangana phakathi kwezinto ze-solder nendawo yebhodi lesifunda.

Ukuhlolwa kokumelana nokushaqeka okushisayo: Lokhu kuhlola kuhlola ukumelana kwebhodi lesekhethi ekuhlukeni kwezinga lokushisa ezindaweni ezishisa kakhulu. Kuhilela ukuveza ibhodi lesifunda emazingeni okushisa aphezulu kanye nokulidlulisela ngokushesha emazingeni okushisa aphansi ukuze kuhlolwe ukumelana kwalo nokushaqeka kokushisa.

11. Umshini Wokuhlola I-X-Ray: Umshini wokuhlola i-X-ray uyakwazi ukungena amabhodi esekethe ngaphandle kwesidingo sokuwahlakaza noma ukubangela umonakalo, ngaleyo ndlela ugweme izindleko kanye nomonakalo ongase ube khona. Ingakwazi ukubona amaphutha ebhodini lesifunda, okuhlanganisa izimbobo zebhamuza, amasekhethi avulekile, amasekhethi amafushane, nemigqa enephutha. Izinto ezisetshenziswayo zisebenza ngokuzimela, zilayisha ngokuzenzakalelayo futhi zikhiphe izinto ezisetshenziswayo, ukuthola, ukuhlaziya, nokuthola okungahambi kahle, nokumaka ngokuzenzakalelayo nokulebula, ngaleyo ndlela kuthuthukiswe ukusebenza kahle kokukhiqiza.

Umshini Wokuhlola I-X-Ray

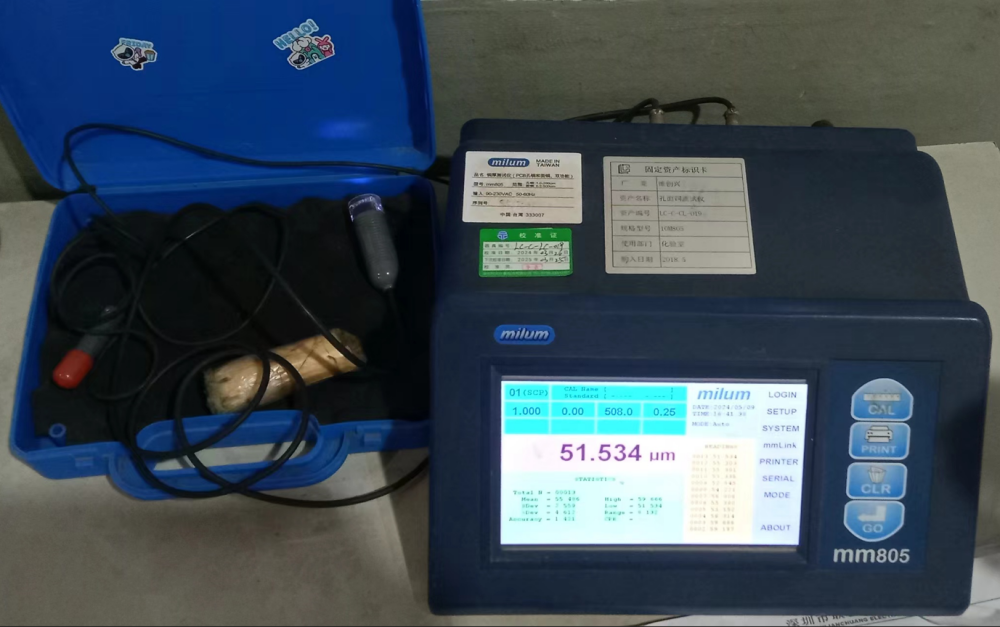

I-Coating Thickness Gauge

12. I-gauge yogqinsi bokwemboza: Phakathi nenqubo yokukhiqiza amabhodi esekethe, ukunamathela okuhlukahlukene (njengokufaka ithini, ukucwebezeliswa kwegolide, njll.) kuvame ukusetshenziswa ukuze kuthuthukiswe ukusebenza kahle nokungagqwali. Kodwa-ke, ukushuba kwe-coating okungafanele kungaholela ezinkingeni zokusebenza. I-gauge yogqinsi bokwemboza isetshenziselwa ukukala ukushuba kwento enamathelayo endaweni yebhodi lesifunda, iqinisekise ukuthi ihlangabezana nezidingo zokuklama.

13. Ithuluzi le-ROHS: Ekukhiqizweni kwamabhodi esekethe aphrintiwe, amathuluzi e-ROHS asetshenziswa ukuze kutholwe futhi kuhlaziywe izinto eziyingozi ezintweni zokwakha, ukuqinisekisa ukuthobelana nezimfuneko zomyalelo we-ROHS. Umyalelo we-ROHS, osetshenziswa yi-European Union, ukhawulela izinto eziyingozi kumishini kagesi nekagesi, okuhlanganisa umthofu, i-mercury, i-cadmium, i-hexavalent chromium, nokunye. Amathuluzi e-ROHS asetshenziselwa ukukala okuqukethwe kwalezi zinto eziyingozi, ukuqinisekisa ukuthi izinto ezisetshenziswa enqubweni yokukhiqiza yamabhodi esekethe aphrintiwe ziyahlangabezana nezimfuneko zomyalelo we-ROHS, okuqinisekisa ukuphepha komkhiqizo nokuvikelwa kwemvelo.

I-ROHS Instrument

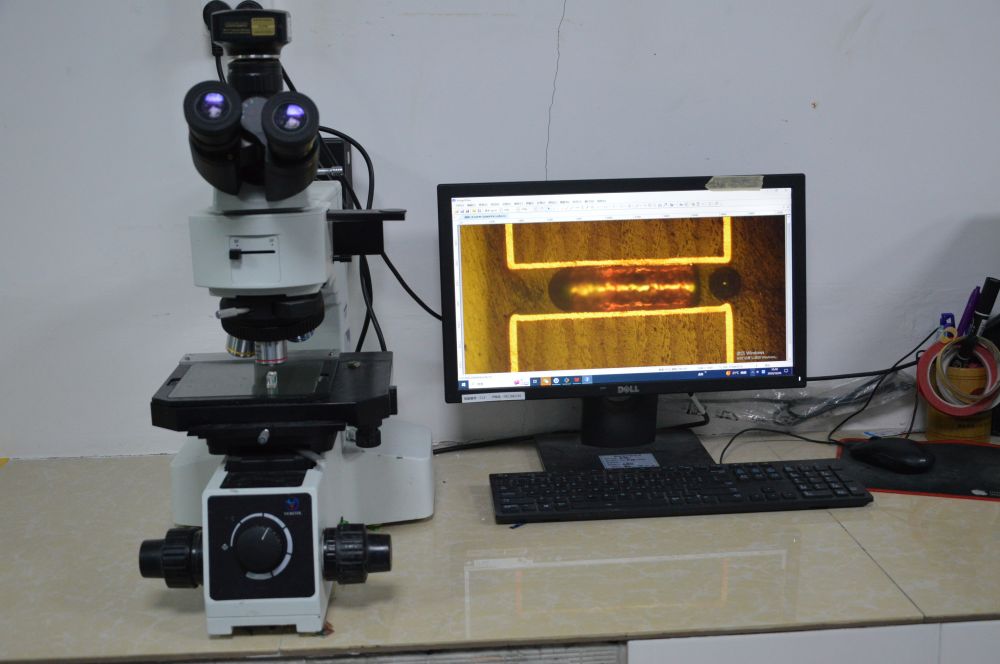

14. Isibonakhulu se-Metallographic: Isibonakhulu se-metallographic sisetshenziswa ngokuyinhloko ukuhlola ukujiya kwethusi kwezendlalelo zangaphakathi nangaphandle, izindawo ezifakwe ugesi, izimbobo ezifakwe ugesi, imaski ye-solder, ukwelashwa kwendawo, kanye nogqinsi lwesendlalelo ngasinye se-dielectric ukuze kuhlangatshezwane nezicaciso zekhasimende.

Isitolo Sesigaba Se-Microscopic

Isigaba 1 se-Microscopic

Isigaba 2 se-Microscopic

I-Hole Surface Copper Tester

15. Isihloli sethusi sembobo: Leli thuluzi lisetshenziselwa ukuhlola ukujiya nokufana kwefoyili yethusi emigodini yamabhodi esekethe aphrintiwe. Ngokuhlonza ngokushesha ugqinsi lwe-copper plating olungalingani noma ukuchezuka kububanzi obucacisiwe, ukulungiswa kungenziwa kunqubo yokukhiqiza ngesikhathi esifanele.

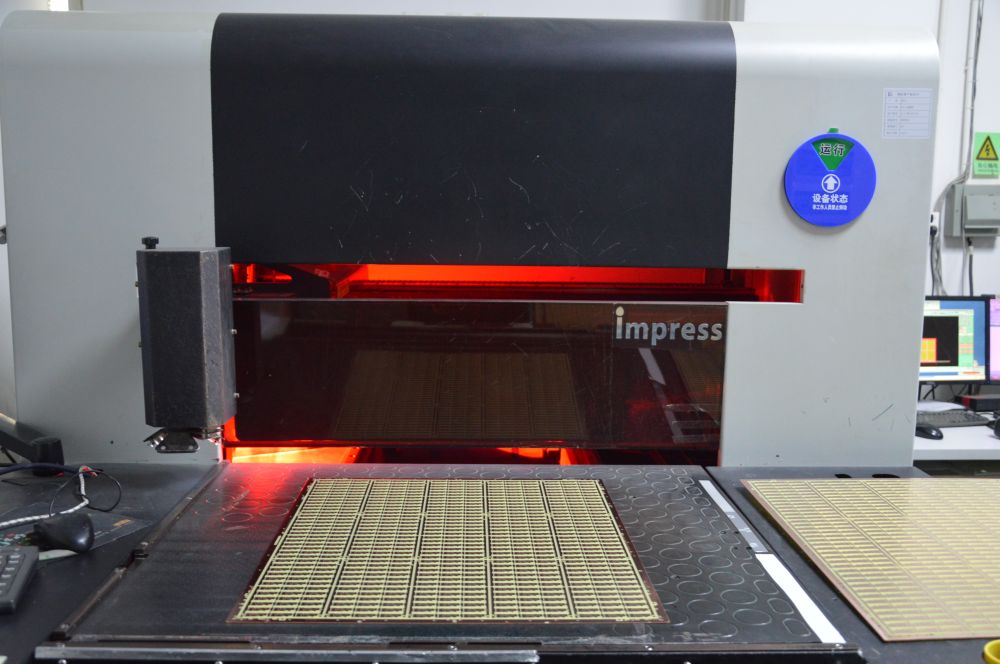

16. I-AOI Scanner, isho ukuthi i-Automated Optical Inspection, iwuhlobo lwesisetshenziswa esisebenzisa ubuchwepheshe be-optical ukuhlonza ngokuzenzakalelayo izingxenye noma imikhiqizo kagesi. Ukusebenza kwayo kuhlanganisa ukuthwebula isithombe esingaphezulu sento ehlolwayo kusetshenziswa isistimu yekhamera yokucaca okuphezulu. Kamuva, ubuchwepheshe bokucubungula izithombe zekhompuyutha buyasetshenziswa ukuze kuhlaziywe futhi kuqhathaniswe isithombe, okuvumela ukutholwa kokulimala okungaphezulu kanye nezinkinga zokulimala entweni okuqondiwe.

Iskena se-AOI

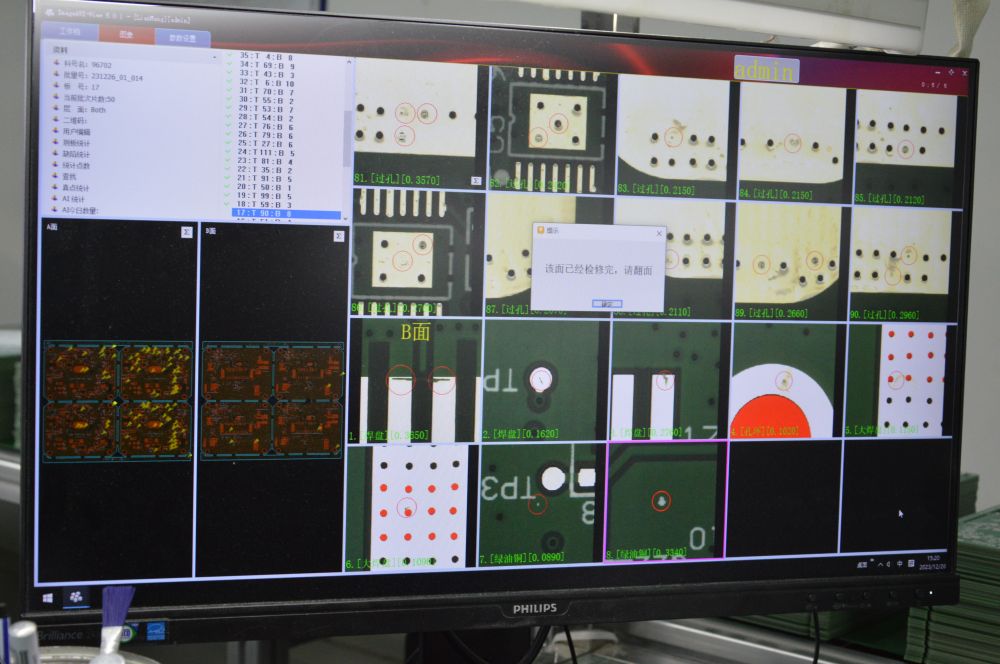

17. Umshini wokuhlola ukubukeka kwe-PCB iyisisetshenziswa esiklanyelwe ukuhlola izinga lokubonwayo lamabhodi esekethe nokuhlonza amaphutha okukhiqiza. Lo mshini unekhamera yokucaca okuphezulu nomthombo wokukhanya ukuze uhlole yonke indawo ye-PCB, uthole ukukhubazeka okuhlukahlukene njengokuklwebheka, ukugqwala, ukungcola, nezinkinga zokushisela. Ngokuvamile, kuhlanganisa amasistimu okuphakelayo nokuthulula okuzenzakalelayo okuphatha amaqoqo amakhulu e-PCB nokuhlukanisa amabhodi agunyaziwe nanqatshiwe. Ngokusebenzisa ama-algorithms okucubungula izithombe, iziphambeko ezikhonjiwe zihlukaniswa futhi zimakwe, kube lula ukulungiswa noma ukuqedwa okulula nokunembe kakhudlwana. Ngenxa ye-automation kanye namakhono athuthukile okucubungula izithombe, le mishini yenza ukuhlola ngokushesha, iqinise ukukhiqiza kanye nezindleko zokusika. Ngaphezu kwalokho, bangagcina imiphumela yokuhlolwa futhi bakhiqize imibiko enemininingwane yokuqapha ikhwalithi kanye nokuthuthukiswa kwenqubo, ekugcineni kukhuphule izinga lomkhiqizo.

Umshini Wokuhlola Ukubukeka 1

Umshini Wokuhlola Ukubukeka 2

Amaphutha Okuhlola Ukubukeka Amakwe

I-PCB Contamination Tester

18. I-PCB ion contamination tester iyithuluzi elikhethekile elisetshenziselwa ukuhlonza ukungcola kwe-ion kumabhodi esekethe aphrintiwe (ama-PCB). Ngesikhathi senqubo yokukhiqiza ugesi, ukuba khona kwama-ion endaweni ye-PCB noma ngaphakathi kwebhodi kungaba nomthelela omkhulu ekusebenzeni kwesekethe kanye nekhwalithi yomkhiqizo. Ngakho-ke, ukuhlolwa okunembile kwamazinga okungcola kwe-ion kuma-PCB kubalulekile ukuze kuqinisekiswe ikhwalithi nokwethembeka kwempahla ye-elekthronikhi.

19. Umshini wokuhlola ukufakwa kwamandla kagesi we-withstand usetshenziswa ukuze uqhube ukwahlukanisa ukumelana nokuhlolwa kwamandla kagesi ukuze kuqinisekiswe ukuthi impahla yokugqumisa kanye nesakhiwo sebhodi lesekethe kuhambisana nemibandela ejwayelekile. Lokhu kuqinisekisa ukuthi ibhodi lesekethe lihlala livalekile ngaphansi kwezimo zokusebenza ezivamile, ukuvimbela ukwehluleka okungase kube khona ukufakwa okungase kubangele izigameko eziyingozi. Ngokuhlaziya imiphumela yokuhlolwa, noma yiziphi izinkinga eziwumsuka ebhodini lesekethe zingabonakala ngokushesha, ziqondise abaklami ekuthuthukiseni ukwakheka kwebhodi kanye nesakhiwo sokwahlukanisa ukuze kukhuliswe izinga nokusebenza kwalo.

Umshini Wokuhlola I-Voltage Insulation

I-Spectrophotometer ye-UV

20. I-spectrophotometer ye-UV: I-spectrophotometer ye-UV isetshenziselwa ukukala izici zokumunca ukukhanya zezinto ezizwela izithombe ezisetshenziswa kumabhodi wesekethe. Lezi zinto, ngokuvamile ama-photoresists asetshenziswa ekukhiqizeni amabhodi esekethe aphrintiwe, anesibopho sokudala amaphethini nemigqa emabhodini.

Imisebenzi ye-spectrophotometer ye-UV ihlanganisa:

1) Ukulinganisa izici zokumunca ukukhanya kwe-photoresist: Ngokuhlaziya izici zokumunca ze-photoresist ebangeni le-ultraviolet spectrum, izinga lokumunca ukukhanya kwe-ultraviolet linganqunywa. Lolu lwazi lusiza ekulungiseni ukubunjwa nokujiya kokumboza kwe-photoresist ukuze kuqinisekiswe ukusebenza kwayo nokuzinza ngesikhathi se-photolithography.

2) Ukunqunywa kwamapharamitha wokuchayeka we-photolithography: Ngokuhlaziywa kwezici zokumunca ukukhanya ze-photoresist, amapharamitha wokuchayeka we-photolithography, njengesikhathi sokuchayeka namandla okukhanya, anganqunywa. Lokhu kuqinisekisa ukuphindaphindwa okunembile kwamaphethini nemigqa ku-photoresist kusuka ebhodini lesekethe.

21. Imitha ye-pH: Enqubweni yokukhiqiza amabhodi esekethe, ukwelashwa kwamakhemikhali okufana nokucotshwa nokuhlanzwa kwe-alkali kuvamile ukusetshenziswa. Imitha ye-pH isetshenziswa ukuqinisekisa ukuthi inani le-pH lesisombululo sokwelashwa lihlala lingaphakathi kwebanga elifanele. Lokhu kuqinisekisa ukusebenza kahle, ukusebenza, kanye nokuzinza kokwelashwa ngamakhemikhali, ngaleyo ndlela kuthuthukiswe ikhwalithi yomkhiqizo nokwethembeka kuyilapho kuqinisekisa indawo yokukhiqiza ephephile.