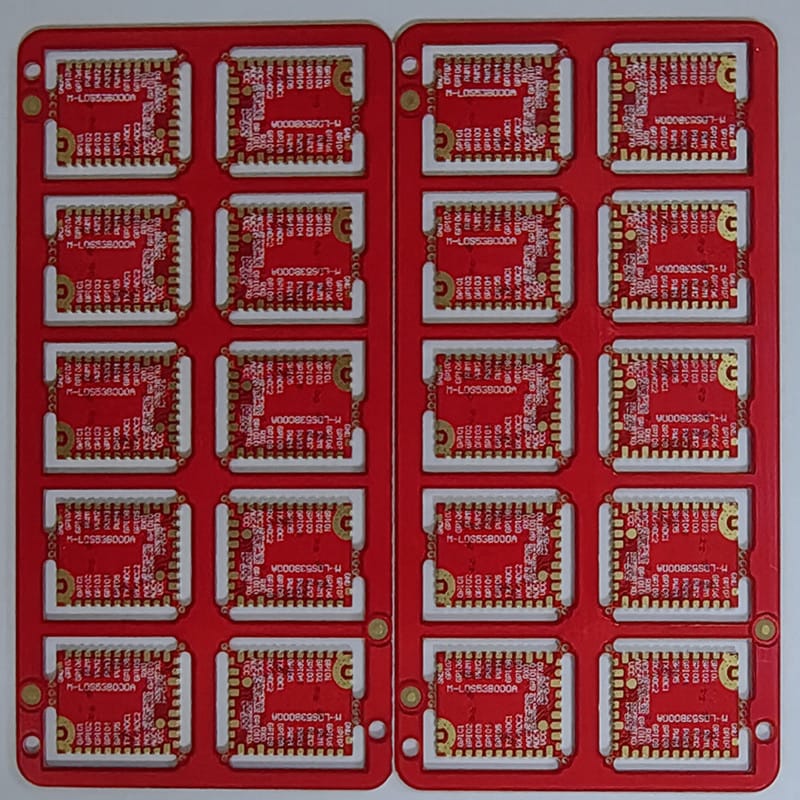

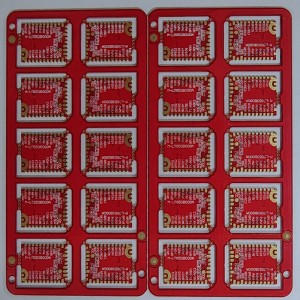

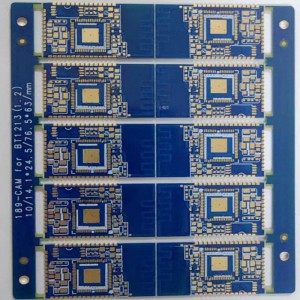

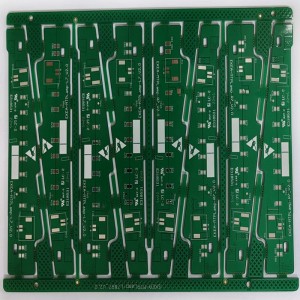

I-Prototype ephrintiwe wesekethe amabhodi RED solder imaski izimbobo castellated

Ukucaciswa komkhiqizo:

| Izinto eziyisisekelo: | I-FR4 TG140 |

| Ubukhulu be-PCB: | 1.0+/-10% mm |

| Ukubalwa Kwesendlalelo: | 4L |

| Ukuqina Kwethusi: | 1/1/1/1 oz |

| Ukwelashwa kwendawo: | ENIG 2U” |

| Imaski ye-solder: | Okubomvu okucwebezelayo |

| Isikrini sikasilika: | Emhlophe |

| Inqubo ekhethekile : | Izimbobo eziyingxenye ye-Pth emaphethelweni |

Isicelo

Izinqubo zama-plated half holes yilezi:

1. Cula imbobo eseceleni ngethuluzi lokusika elimise okuka-V kabili.

2. Umshini wokubhoboza wesibili wengeza izimbobo eziqondisayo ohlangothini lwembobo, ususa isikhumba sethusi kusenesikhathi, unciphisa ama-burrs, futhi usebenzisa ama-groove cutters esikhundleni sokubhoboza ukuze ukhulise isivinini nokwehla.

3. Gxilisa ithusi ku-electroplate i-substrate, ukuze ungqimba lwethusi lufakwe i-electroplated odongeni lwembobo yembobo eyindilinga emaphethelweni ebhodi.

4. Ukukhiqizwa kwesekethe yongqimba yangaphandle ngemva kokulahlwa, ukuchayeka, nokuthuthukiswa kwe-substrate ngokulandelana, i-substrate ingaphansi kwe-copper plating yesibili kanye ne-tin plating, ukuze ungqimba lwethusi odongeni lwembobo yembobo eyindilinga onqenqemeni lwebhodi luqiniswe futhi ungqimba lwethusi lumbozwe ungqimba lwethini lokumelana nokugqwala;

5. Ukwakhiwa kwehhafu yembobo ukusika imbobo eyindilinga onqenqemeni lwebhodi ibe uhhafu ukuze wenze uhhafu wembobo;

6. Esinyathelweni sokususa ifilimu, ifilimu ye-anti-electroplating ecindezelwe phakathi nenqubo yokucindezela ifilimu isusiwe;

7. Ukufaka i-substrate kuqoshwe, futhi ithusi eliveziwe engxenyeni yangaphandle ye-substrate isuswa ngokufaka;

8. I-tin ehlubula i-substrate ikhishwa ithini, ukuze ithini esodongeni lwembobo yesigamu ingasuswa, futhi ungqimba lwethusi odongeni lwembobo yesigamu luvezwe.

9. Ngemva kokwenza, sebenzisa itheyiphu ebomvu ukuze unamathisele amabhodi amayunithi ndawonye, bese ususa ama-burrs ngomugqa wokufaka i-alkaline.

10. Ngemuva kokufakwa kwethusi kwesibili nokufakwa kwe-tin ku-substrate, imbobo eyindilinga emaphethelweni ebhodi inqunywa ngesigamu ukuze yenze umgodi wesigamu, ngoba ungqimba lwethusi odongeni lwembobo lumbozwe ungqimba lwe-tin, futhi ungqimba lwethusi lodonga lwembobo luhlangene ngokuphelele nongqimba lwethusi lwengqimba yangaphandle ye-substrate esebenzayo ingavimbela ukuxhuma okuqinile kwe-substrate. udonga lwembobo ekukhishweni noma i-copper warping lapho usikwa;

11. Ngemva kokuqedwa kokwakhiwa kwe-half-hole, ifilimu iyasuswa bese igxilwa, ukuze indawo yethusi ingabi ne-oxidized, igweme ngokuphumelelayo ukuvela kwethusi elisele noma ngisho nesifunda esifushane, futhi sithuthukise izinga lokukhiqiza lebhodi lesifunda le-PCB le-metallized half-hole.

Imibuzo Evame Ukubuzwa

Imbobo ewuhhafu eplathiwe noma i-castelated-hole, iwunqenqema olumise okwesitembu ngokusikwa phakathi kohlaka. I-plated half-hole iyizinga eliphakeme lemiphetho ehlanganisiwe yamabhodi esekethe aphrintiwe, ngokuvamile asetshenziselwa ukuxhumana kwebhodi kuya ebhodini.

I-Via isetshenziswa njengoxhumano phakathi kwezendlalelo zethusi ku-PCB kuyilapho i-PTH ngokuvamile yenziwa ibe nkulu kune-vias futhi isetshenziswa njengembobo ecwecwe ukuze kwamukelwe izingxenye eziholayo - njengezinqamuleli ezingezona ze-SMT, ama-capacitor, nephakheji ye-DIP IC. I-PTH ingasetshenziswa futhi njengezimbobo zokuxhuma ngomshini kuyilapho i-vias ingase ingasebenzi.

I-plating emigodini yokudlula iyithusi, i-conductor, ngakho-ke ivumela ukuqhutshwa kukagesi ukuhamba ebhodini. I-Non-plated ngokusebenzisa izimbobo ayinayo i-conductivity, ngakho-ke uma uyisebenzisa, ungaba namathrekhi ethusi awusizo ohlangothini olulodwa lwebhodi.

Kunezinhlobo ezi-3 zemigodi ku-PCB, ePlated Through Hole (PTH), Non-Plated Through Hole (NPTH) kanye ne-Via Holes, lezi akufanele kudidaniswe ne-Slots noma Ukusika.

Kusuka ku-IPC ejwayelekile, ingu-+/-0.08mm ye-pth, kanye ne-+/-0.05mm ye-npth.