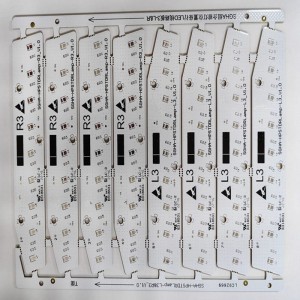

Quick Turn pcb surface treatment HASL LF RoHS

Ukucaciswa komkhiqizo:

| Izinto eziyisisekelo: | I-FR4 TG140 |

| Ubukhulu be-PCB: | 1.6+/-10%mm |

| Ukubalwa Kwesendlalelo: | 2L |

| Ukuqina Kwethusi: | 1/1 oz |

| Ukwelashwa kwendawo: | I-HASL-LF |

| Imaski ye-solder: | Emhlophe |

| Isikrini sikasilika: | Mnyama |

| Inqubo ekhethekile : | Okujwayelekile |

Isicelo

Inqubo ye-HASL yebhodi lesifunda ngokuvamile ibhekisela kunqubo ye-pad HASL, okuwukuthi ukugqoka ithini endaweni ye-pad ebusweni bebhodi lesifunda. Ingadlala indima ye-anti-corrosion kanye ne-anti-oxidation, futhi ingaphinda ikhulise indawo yokuxhumana phakathi kwephedi nedivayisi edayisiwe, futhi ithuthukise ukuthembeka kwe-soldering. Ukugeleza kwenqubo ethile kuhlanganisa izinyathelo eziningi ezinjengokuhlanza, ukufakwa kwamakhemikhali kathayela, ukucwiliswa emanzini, nokuwasha. Khona-ke, ngenqubo efana ne-hot soldering, izosabela ukwakha isibopho phakathi kwe-tin kanye nedivaysi ye-splice. Ukufafaza ngamathini kumabhodi esekethe kuyinqubo esetshenziswa kakhulu futhi isetshenziswa kakhulu embonini yokukhiqiza ugesi.

I-HASL eholayo kanye ne-HASL engenamthofu ubuchwepheshe obubili bokwelapha obungaphezulu obusetshenziswa kakhulukazi ukuvikela izingxenye zensimbi zamabhodi esekethe ekutheni zingagqwali kanye ne-oxidation. Phakathi kwazo, ukwakheka kwe-HASL yomthofu yakhiwe ngamathini angama-63% kanye nokuhola okungu-37%, kuyilapho i-HASL engenamthofu yakhiwa ithini, ithusi nezinye izakhi (njengesiliva, i-nickel, i-antimony, njll.). Uma kuqhathaniswa ne-HASL esekelwe kumthofu, umehluko phakathi kwe-HASL engenawo umthofu ukuthi ihambisana kakhulu nemvelo, ngoba umthofu uyinto eyingozi ebeka imvelo nempilo yabantu engozini. Ngaphezu kwalokho, ngenxa yezakhi ezihlukene eziqukethwe ku-HASL engenamthofu, izakhiwo zayo ze-solder kanye nogesi zihluke kancane, futhi zidinga ukukhethwa ngokuvumelana nezidingo ezithile zohlelo lokusebenza. Ngokuvamile, izindleko ze-HASL engenamthofu ziphakeme kancane kune-HASL yomthofu, kodwa ukuvikelwa kwayo kwemvelo nokusebenza kwayo kungcono, futhi kuthandwa abasebenzisi abaningi ngokwengeziwe.

Ukuze uhambisane nomyalelo we-RoHS, imikhiqizo yebhodi lesifunda idinga ukuhlangabezana nalezi zimo ezilandelayo:

1. Okuqukethwe komthofu (Pb), i-mercury (Hg), i-cadmium (Cd), i-hexavalent chromium (Cr6+), i-polybrominated biphenyls (PBB) nama-diphenyl ethers enziwe nge-polybrominated (PBDE) kufanele kube ngaphansi kwenani lomkhawulo elishiwo.

2. Okuqukethwe kwezinsimbi eziyigugu njenge-bismuth, isiliva, igolide, i-palladium, neplatinamu kufanele kube ngaphakathi kwemikhawulo enengqondo.

3. Okuqukethwe kwe-halogen kufanele kube ngaphansi kwenani lomkhawulo elishiwo, okuhlanganisa i-chlorine (Cl), i-bromine (Br) ne-iodine (I).

4. Ibhodi lesifunda kanye nezingxenye zalo kufanele zibonise okuqukethwe kanye nokusetshenziswa kwezinto ezinobuthi ezifanele neziyingozi. Lokhu okungenhla kungenye yezimo eziyinhloko zokuthi amabhodi esekethe ahambisane nomyalelo we-RoHS, kodwa izidingo ezithile zidinga ukunqunywa ngokuvumelana nemithetho yendawo kanye namazinga.

Imibuzo Evame Ukubuzwa

I-HASL noma i-HAL (yokulinganisa komoya oshisayo (i-solder)) iwuhlobo lokuqeda olusetshenziswa kumabhodi esekethe aphrintiwe (ama-PCB). I-PCB ivamise ukucwiliswa kubhavu we-solder encibilikisiwe ukuze zonke izindawo zethusi eziveziwe zimbozwe nge-solder. I-solder eyeqile isuswa ngokudlula i-PCB phakathi kwemibese yomoya oshisayo.

I-HASL (Ejwayelekile): Ngokuvamile i-Tin-Lead – HASL (Ihola Ngokukhululekile): Ivamise ukuba i-Tin-Copper, Tin-Copper-Nickel, noma i-Tin-Copper-Nickel Germanium. Ugqinsi olujwayelekile: 1UM-5UM

Ayisebenzisi i-Tin-Lead solder. Kunalokho, i-Tin-Copper, Tin-Nickel noma i-Tin-Copper-Nickel Germanium ingasetshenziswa. Lokhu kwenza i-LEad-Free HASL ibe ukukhetha ukonga nokuthobela i-RoHS.

I-Hot Air Surface Leveling(HASL) isebenzisa umthofu njengengxenye ye-solder alloy yayo, ethathwa njengeyingozi kubantu. Kodwa-ke, i-Lead-free Hot Air Surface Leveling (LF-HASL) ayisebenzisi umthofu njengengxube ye-solder, okwenza iphephe kubantu kanye nemvelo.

I-HASL iyonga futhi itholakala kabanzi

Ine-solderability enhle kakhulu nempilo enhle yeshelufu.