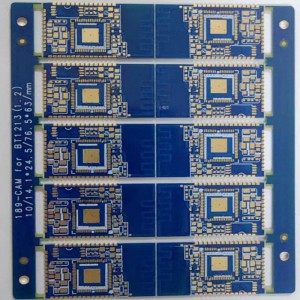

I-Pcb prototype pcb eyenziwe ngemaski ye-solder eluhlaza okwesibhakabhaka egcwele izimbobo ezinezimbobo

Ukucaciswa komkhiqizo:

| Izinto eziyisisekelo: | I-FR4 TG140 |

| Ubukhulu be-PCB: | 1.0+/-10% mm |

| Ukubalwa Kwesendlalelo: | 2L |

| Ukuqina Kwethusi: | 1/1 oz |

| Ukwelashwa kwendawo: | ENIG 2U” |

| Imaski ye-solder: | Okuluhlaza okwesibhakabhaka okucwebezelayo |

| Isikrini sikasilika: | Emhlophe |

| Inqubo ekhethekile : | Izimbobo eziyingxenye ye-Pth emaphethelweni |

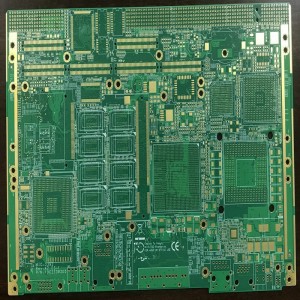

Isicelo

Ibhodi le-PCB elinembobo ewuhhafu lisho inqubo yesibili yokubhoboza nokuma ngemva kokuba imbobo yokuqala ibhoboziwe, futhi ekugcineni ingxenye yomgodi oyinsimbi igodliwe. Inhloso ukushisela ngokuqondile unqenqema lwembobo onqenqemeni oluyinhloko ukuze konge izixhumi nesikhala, futhi kuvame ukuvela kumasekhethi esignali.

Amabhodi esekethe anembobo ehhafu ajwayele ukusetshenziselwa ukukhweza izingxenye ze-elekthronikhi ezinobukhulu obuphezulu, njengamadivayisi eselula, amawashi ahlakaniphile, imishini yezokwelapha, imishini yomsindo nevidiyo, njll. Anika amandla ukuminyana kwesifunda okuphakeme kanye nezinketho eziningi zokuxhumana, okwenza amadivaysi kagesi abe mancane, alula futhi asebenze kahle.

Imbobo enguhhafu engagqitshiwe emaphethelweni e-PCB ingenye yezinto ezivame ukusetshenziswa eziklanyweni zenqubo yokukhiqiza ye-PCB, futhi umsebenzi wayo oyinhloko ukulungisa i-PCB. Enqubweni yokukhiqiza ibhodi le-PCB, ngokushiya izimbobo eziyingxenye ezindaweni ezithile onqenqemeni lwebhodi le-PCB, ibhodi le-PCB lingalungiswa kudivayisi noma endlini ngezikulufo. Ngesikhathi esifanayo, phakathi nenqubo yokuhlanganisa ibhodi le-PCB, imbobo enguhhafu isiza futhi ukubeka nokuqondisa ibhodi le-PCB ukuze kuqinisekiswe ukunemba nokuzinza komkhiqizo wokugcina.

Imbobo yesigamu efakwe eceleni kwebhodi lesifunda ukuthuthukisa ukuthembeka kokuxhumeka kohlangothi lwebhodi. Ngokuvamile, ngemva kokusikwa kwebhodi lesifunda eliphrintiwe (PCB), ungqimba lwethusi oluveziwe onqenqemeni luzovezwa, oluthambekele ekubeni ne-oxidation kanye nokugqwala. Ukuze uxazulule le nkinga, ungqimba lwethusi luvame ukumbozwa ungqimba oluvikelayo ngokufaka i-electroplating onqenqemeni lwebhodi lube yimbobo ehhafu ukuze kuthuthukiswe ukumelana ne-oxidation nokumelana nokugqwala, futhi kungandisa indawo yokushisela futhi kuthuthukise ukuthembeka kokuxhumeka.

Enkambweni yokucubungula, indlela yokulawula ikhwalithi yomkhiqizo ngemva kokwenza izimbobo ze-semi-metallized emaphethelweni ebhodi, njengameva ethusi odongeni lwembobo, njll., bekulokhu kuyinkinga enzima ohlelweni lokucubungula. Kulolu hlobo lwebhodi olunomugqa wonke wezimbobo ze-semi-metallized Ibhodi le-PCB libonakala ngobubanzi bembobo encane, futhi lisetshenziselwa kakhulu ibhodi lendodakazi yebhodi lomama. Ngalezi zimbobo, ihlanganiswe nebhodi lomama kanye nezikhonkwane zezingxenye. Lapho i-soldering, izoholela ekuhlanganisweni okubuthakathaka, i-solder yamanga, kanye nokujikeleza okufushane kwebhuloho phakathi kwamaphini amabili.

Imibuzo Evame Ukubuzwa

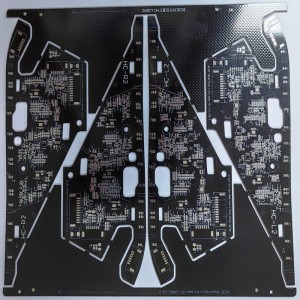

Kungase kube usizo ukubeka izimbobo ezinamapulangwe (PTH) onqenqemeni lwebhodi. Isibonelo uma ufuna ukudayisela ama-PCB amabili komunye nomunye nge-engeli engu-90° noma lapho unamathisela i-PCB ku-casing yensimbi.

Isibonelo, inhlanganisela yamamojula ayinkimbinkimbi e-microcontroler anama-PCB ajwayelekile, aklanywe ngawodwana.Ezinye izinhlelo zokusebenza ziyizibonisi, i-HF noma amamojula e-ceramic adayiswa ebhodini lesifunda eliphrintiwe.

Ukubhoboza- okugqitshwe ngembobo (PTH) - ukufakwa kwephaneli - ukudluliswa kwesithombe - i-pattern plating -pth isigamu sembobo- striping - etching - solder mask - isikrini sikasilika - ukwelashwa kwendawo.

1.Ububanzi ≥0.6MM;

2.Ibanga phakathi komkhawulo wembobo ≥0.6MM;

3. Ububanzi bendandatho yokufaka idinga u-0.25mm;

I-Half-hole iyinqubo ekhethekile. Ukuze kuqinisekiswe ukuthi kunethusi emgodini, kufanele kugaywe kuqala ngaphambi kokucwenga inqubo yethusi. I-PCB yembobo ewuhhafu ejwayelekile incane kakhulu, ngakho-ke izindleko zayo zibiza kakhulu kune-PCB evamile.